Recycling White Metals: The Process

Recycling White Metals

Recycling white metals is one of the most practiced types of recycling. White metals are white or silvery alloys, especially tin-based alloys usually used for the surfaces of bearings. These alloys may contain tin, cadmium, zinc, lead, and bismuth. They are Babbitt metals with low melting points.

Manufacturers use white metals for producing:

- Bearings

- Jewelry

- Fusible plugs

- Sculptures

- Medals

- Beverage Cans

White metals are common choices for the production of modern jewelry i.e. rings. They have high market value over gold or rosy metals. This is because silvery-white metals compliment skin tone and are timeless, unlike the gold alloys. Examples of white metals are: tin, silver, white, gold, nickel, lead, and iron.

White metals are powerful conductors of heat and electricity and they are also known to be powerful amplifiers. This now explains why silver is the best conductor. White metals are also non-ferrous metals—They don’t have magnetic features. Their alloys are soft, ductile but tough. They also have a high coefficient of friction.

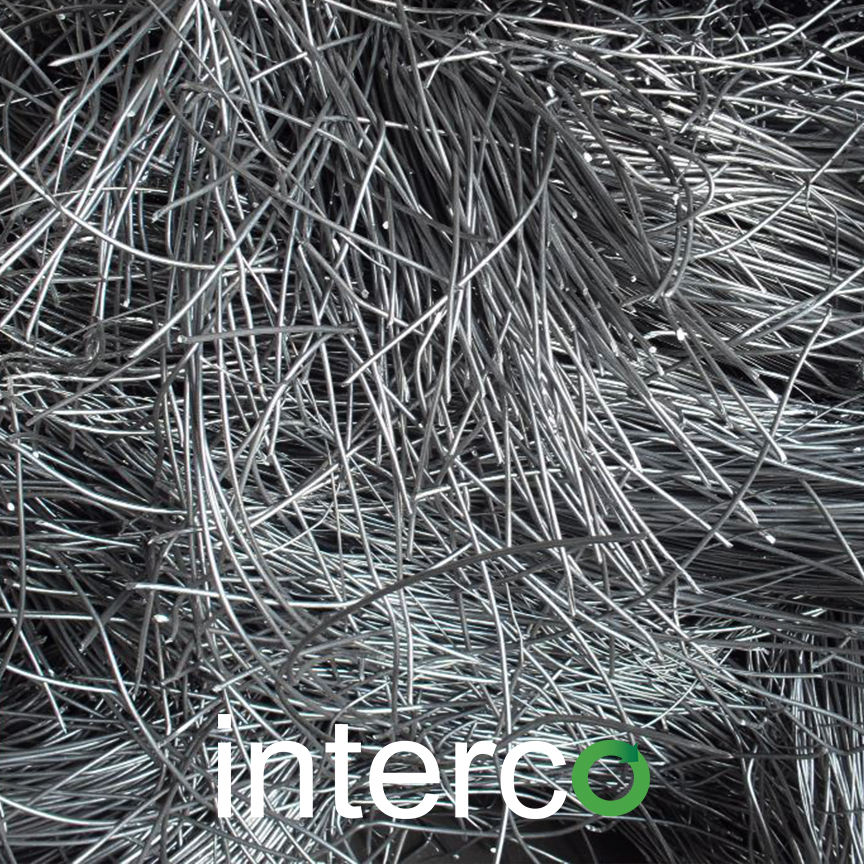

Recycling of White Metals

Recycling white metals is usually performed by professional recyclers. These recyclers buy white metal scraps from scrap yards, processes and recycle them. Recyclers recycle white metals in a similar way that metals are generally recycled. They subject the metals to immense heat temperature that is above their melting point and they are cast into molds. Recycling white metals is essential so that they process the scraps into new metals of better quality. The most common use of white metals is in the manufacture of bearings.

Examples of the items that use bearings are: gearboxes, air planes, turbines, pumps, compressors, fans, etc.

Prior to this list, the need for recycling white metals is essential so that manufacturers can manufacture these devices. Also, recycling these worn out or outdated devices help protect the natural source of white metals from being total depletion.

How to Recycle White Metals

Recycling white metals is straightforward without much complexity. Recyclers like Interco specialize in recycling white metals and its scraps for further use and processing.

The following steps involved in recycling white metals are:

- The recyclers collect or buy the scraps of white metals from scrap yards or deposits.

- A metal shredder shreds the white metals into smaller pieces.

- Then, they transport these shreds into a furnace. However, white metal alloys don’t have high melting points. The temperature should be set a little above their melting points i.e. 350◦C. This is to ensure uniformity in the molten state.

- They mix a few additives i.e. chemicals to improve its quality.

- Next, recyclers cast the molten white metal into mold or ingots and leave to cool.

- They will transport these casts to manufacturing or industrial companies for further processing.

Conclusion

The application of white metals today may not be outspoken, but it is indeed important for the possibility of many inventions. Furthermore, recycling white metals properly helps reduce pollution by preventing it from ending up in a landfill. Also, recycling white metals helps provide job opportunities for prospective recyclers.