How Should A Company go about Recycling Copper Transformers?

How Should A Company go about Recycling Copper Transformers?

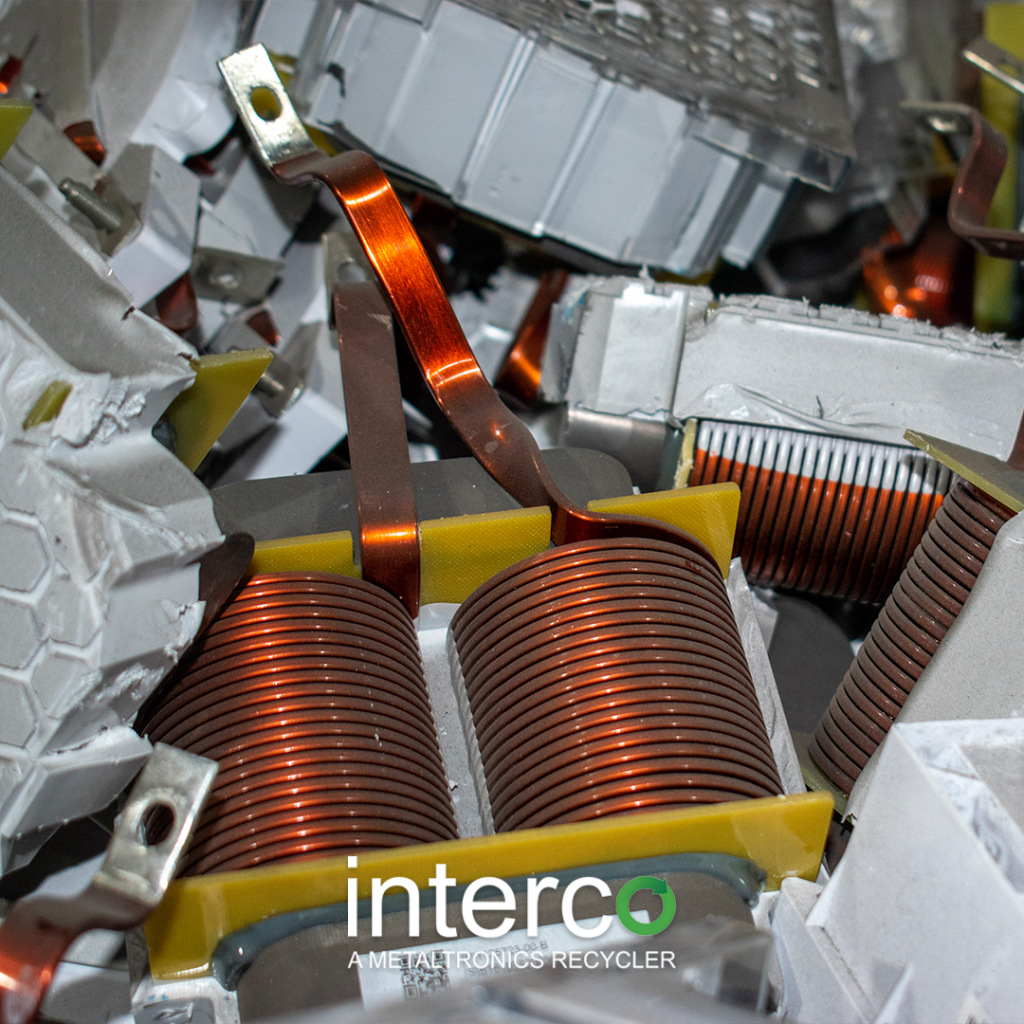

Since companies all have some sort of transformer, they will all need a lesson in recycling copper transformers. A transformer is an electrical device consisting of two or more coils of wire used to transfer electrical energy by means of a changing magnetic field.

Transformers, like anything else, have an expiration date, where they will no longer be able to work properly. A transformer’s life expectancy is between 30 to 50 years, so companies will not always have to worry about it. But when they do, it can seem like a challenging task.

Interco works with companies to recycle transformers. In fact, the company recycles copper and aluminum transformers.

How Do You Know If A Transformer Has Gone Bad?

There are a few ways to check to see if a transformer has gone bad:

- Perform a visual inspection. Common things you will see if a transformer has gone bad is bulges or burn marks. If you see this, then you do not need to test it, it needs to be replaced!

- Check the schematic circuit. When you look at a schematic, you can see how all the parts of the circuit are connected. You can check to make sure everything is connected.

- Find the input and output. You can easily tell if a transformer has gone bad if the output is not the same as the input.

- Check the voltage. You can check the voltage by checking the top center tap. If there is power going to the unit, check for a bad connection from the power connection block to the unit itself.

- Inspect the meter. If your meter does not show any voltage, then the problem likely lies with the unit itself and will need to be replaced.

- Evaluate the power. A bad transformer will have weak or no power. A simple way to check the power is to turn the unit off and on again.

- No voltage. If there is no power, there may be no voltage at all. You can quickly determine if voltage is the issue, by checking the voltage points. If there is no voltage or weak voltage, the problem may have some root causes. One could be the control board.

When you have determined the transformer has gone bad, then you will need to replace it. Then companies have to face the issue of what to do with the old transformer. Recycling copper transformers with a recycling center, like Interco, is the best option.

Why Is It Important to Recycle Transformers?

It is important to recycle transformers because they contain toxic materials. When a transformer is running, it generates heat. If the coils are not protected, then they will melt. This can become extremely toxic because the coil is commonly made of copper. So, manufacturers use polychlorinated biphenyls. This is a manmade chemical that is an oily liquid. This chemical is resistant to extreme temperature and pressure, which makes it the perfect chemical to protect the coils.

If this chemical were to leak in a landfill, it would negatively affect the environment and the people living in the surrounding area. It could potentially leak into our water supply and cause extreme health problems. That is why the best way for companies to get rid of their transformers is to recycle them.

Recycling Copper Transformers: The Process

The process to recycle transformers should be performed safely using the following steps:

- First, they remove the transformer from the device.

- After it arrives at a facility, they test the equipment and oils for PCBs.

- Then they process the oil and clean it to reuse.

- They then disassemble the transformer and decide whether the parts will be disposed of or reused.

- Then, they chop the coils, so they will be easy to melt and recycle.

- They then recycle the tank as a whole.

Since scrap transformers contain toxic materials, it is important that the process is done in a controlled environment. Companies should work with a certified recycling center, like Interco, so they know that the recycler is using the best recycling practices out there.

About Interco

Interco is a global recycling company providing metals, computers and electronics recycling services to industrial, dealer, and government organizations throughout the western hemisphere. The facility has a 145,000 sqft. processing plant committed to the processing of computers, electronics, and batteries with the remainder of the indoor facility used for the processing of nonferrous industrial metals.

The facility has five buildings — approximately 400,000 square feet total — on more than 35 acres. The company facility has more than 20 inbound and outbound docks for receiving and shipping nonferrous scrap material as well as a railroad rail spur to load rail cars.

The company is within proximity to four major interstates (I-44, I-55, I-64, and I-70) while centrally located just across the Mississippi River from St. Louis, Missouri in Madison, Illinois. The company offers a convenient delivery location as the facility is near four major interstates (I-44, I-55, I-64, and I-70) that intersect all of the Midwest and Central USA.

Conclusion

In conclusion, companies will eventually need to replace their old transformers. Recycling copper transformers is the best way to discard any old transformer. Working with a recycling center, like Interco, makes this process extremely easy. With a staff of 100 full time employees, the company receives, processes, upgrades, repackages and ships approximately 15,000 tons of material monthly. To learn more, click here.