Recycle Networking Equipment

Recycle Networking Equipment

In the current digital revolution, businesses are forced to discard outdated, faulty scrap network gear in place of new tech. Interco has the means to source and recycle networking equipment. The company sources material from industrial sources, scrap dealers and data centers across North America. In addition, the company disassembles the scrap network gear and extract the precious metals and other valuable materials.

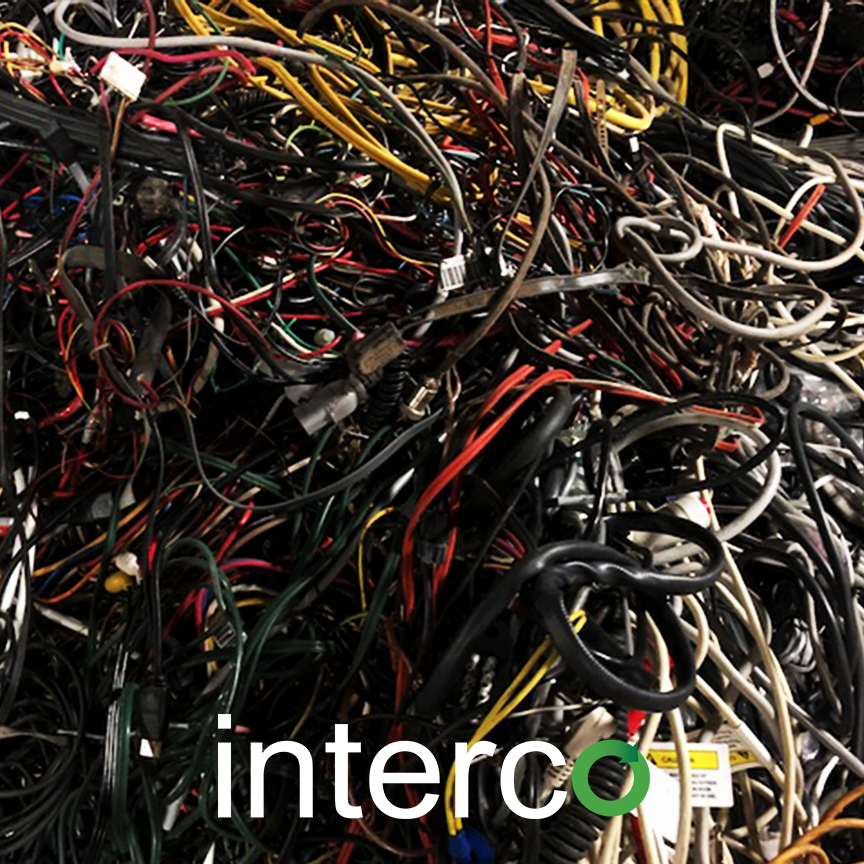

Scrap Network Gear

According to the EPA, US companies recycled 1.2 million tons of consumer electronics in 2015. A significant portion of this comes from companies who recycle networking equipment such as scrap network gear. Examples of scrap network gear include:

- Routers

- Switches

- Network Cards

- Repeaters

- Modems

The Recycling Process

Additionally, Interco has a two-step process. The company uses this process to recycle networking equipment. First, the recycler sorts the equipment by type and material construction. When possible, the Interco staff separates the plastic and steel parts from the network gear. Next, dis-assemblers remove printed circuit boards (PCB) and other material. The other material includes computer wire, hard drives, power supplies, memory, processors and other parts.

Many of the Interco suppliers follow the Department of Defense standards for data destruction and remove the data from the devices. They mostly perform this step prior to shipping the equipment to Interco. Others require the scrap network gear be destroyed. This often means the company deploys a material shredder. A shredder breaks the scrap networking gear into small enough pieces. This results in unrecognizable data that allows the precious metals to be more efficiently recovered.

The Shredder

Next, Interco shreds the scrap network gear into raw commodities such as nonferrous metals and precious metals. The shredder even sorts out the plastic and steel. The nonferrous metals include, but are not limited to:

- Aluminum

- Copper

- Zinc

Accordingly, when recycle networking equipment, Interco separates the white metals from the red metals and recycles them. Interco practices an effective and efficient recycling process:

- First, a state-of-the-art metal shredder shreds the white metals into small pieces – usually two-inch squares. At that point, they transport these shreds into a heater.

- Note that white metal compounds do not have high dissolving focuses. The temperature should be set a little over their liquefying focuses This could mean 350 degrees Celsius as an example. This guarantees consistency in the liquid state.

- Recyclers then blend a couple of added substances like synthetic compounds to improve its quality.

- Next, they cast the liquid white metal into forms to make ingots and leave to cool.

- Finally, they transport ingots to assembling or mechanical organizations for further handling.

Red Metals Shredding

Red metals have a similar process for recycling. However, it is a little different:

- Accumulation: Above all else, experts gather the different red metal pieces. Certain assembling organizations purchase these pieces from individuals as

recycle networking equipment. They sell their out of date hardware, parts or instruments made of red metals. They call this procedure of purchasing the “gathering procedure.” In like manner, one of the biggest sources of red metals speak to materials made of copper for example wires. - Arranging: Reusing scrap red metals takes off after accumulation. Thus, Interco sorts the gathered pieces as per their characteristic qualities. Recyclers separate the untainted copper from its amalgams (metal, bronze, etc.). Processors use magnets and optical separation sensors and observe the red metal sort. After this, they regularly convey the material to a metal shredder to set it up for the following step.

- Softening and Cleaning: Moreover, after the recycler gathers and arranges these materials. Then they expose the metals to high temperature to liquefy. The purging helps guarantee the contaminants dissipate and achieve high caliber status.

- Cementing: At last, after the pieces have been liquefied and refined, manufacturing plants cast them into shapes. The liquid state makes it possible contingent upon their motivation and leave them to dry.

Conclusion

In conclusion, the process used to recycle networking equipment and scrap network gear is important and complex. The digital age forces us to continue to innovate in all that we do. Furthermore, the continued updating and improvement in the process helps Interco maintain efficiencies.

Interco represents the best of the recycling world. The company relies on its experience so you can recycle your networking equipment and scrap network gear on a local and global scale with confidence.