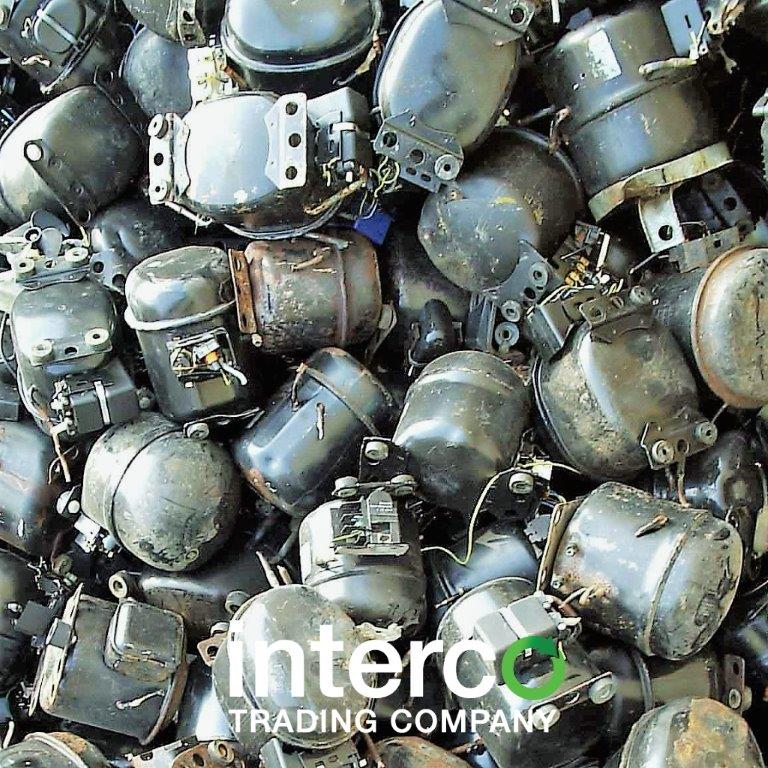

Recycling Sealed Units

Recycling sealed units represent one of the most common sectors of recycling today. What are sealed units? They are compressors and gas chambers mainly found in the following:

- Refrigerators

- Air conditioners

- Freezers

The compressors pressurize the gas creating a strong condensation. They have a mechanical shelf life of a few hundred hours after which they become inefficient and turn out to be a large heavy waste item. Consequently, these items find themselves on the way to the scrapyards to be recycled.

These units occupy some of the largest real estates in scrap yards. Properly managed, they avoid becoming a menace through landfills and land pollution. Recyclers purchase scrap compressors and strip them down to their component. Then they recycle and recondition the components and use them in making new units.

So why is recycling sealed units important today?

Why is Recycling Sealed Units Important?

When these compressors wear out or damaged, they turn into solid waste items. If not carefully managed, they could cause issues of contamination to landfills. In addition, all of the compressor components are recyclable; so why not recycle them and reduce solid waste?

If the inner gas leaks, the could prove extremely dangerous to nearby wildlife, agricultural and residential lands. Furthermore, indiscriminate dumping of these units could cause the inner oil to leak into water sources or on soil and could pollute both the soil and water.

Natural Resources Matter

Recycling sealed units helps protect natural resources and reduce pollution (air and land). Sometimes, these sealed units may have punctures in them which allows the remaining gases to leak into the environment. The gases could be toxic (i.e. ammonia) and lead to pollution.

Also, these sealed units are metallic with motors and copper windings constituting the core. While scrap dealers classify inner motors as low-grade scrap, the copper wire represent some of the most valuable and available industrial metal scraps.

Recyclers who properly dispose of these gases in a safe way do more than save natural resources. They could save the environment as well. Recyclers often reduce pollution while saving valuable resources. This is often referred to as Urban Mining.

Furthermore, recyclers add to the economy by adding to their economic contribution. The sealed units help make planet earth greener and safer.

What Happens When Recycling Sealed Units?

Not much occurs when recycling sealed units. The process is pretty straightforward but requires meticulousness and dexterity. That is why it is best to leave the process to professional recyclers.

- Recyclers buy scrap compressors and other forms of sealed units from scrap yards and take them to the recycling plant.

- The recycling company then safely displaces or filter out any gas left in the units. This helps curb pollution.

- Strip the sealed units to its individual components i.e. motors, copper wiring, screws, rings, bearings etc.

- After separating components, take valuable parts like rings and bearing back to the assembling factory if they are still in good shape. If they are not, recycle them.

- Recyclers separate the metallic parts of the units according to their types i.e. copper, steel, etc.

- The recyclers then melt the metals in furnaces of high temperature and cast the molten metals into new units.

- After cooling, test the refurbished unit for leaks and noise to assure consumer’s quality and reduce future cases of pollution.

Conclusion

Note, don’t try to recycle any compressors by yourself. You can take your scrap sealed units to your local junkyard. They will send them to Interco as this is their area of expertise: recycling sealed units. Contact them here.