Choose a Certified Scrap Lithium-ion Batteries Recycler

Each year, thousands of tons of lithium-ion batteries are disposed of in less-than-ideal ways.

When choosing a certified scrap lithium-ion batteries recycler, it is important to make sure they can provide their federal, state, local, and occupational safety compliance records.

Lithium-ion is reasonably harmless but spent packs should be disposed of properly.

There are many professions and industries in which certification of some kind is essential. With new regulations surrounding best recycling and disposition practices emerging all the time, it is important to choose a company with the proper credentials.

First, your business will want to match your recycling needs with the services offered. Lithium-ion batteries are valuable for their use and composition. It is important that the disposal service picked can recycle lithium-ion batteries.

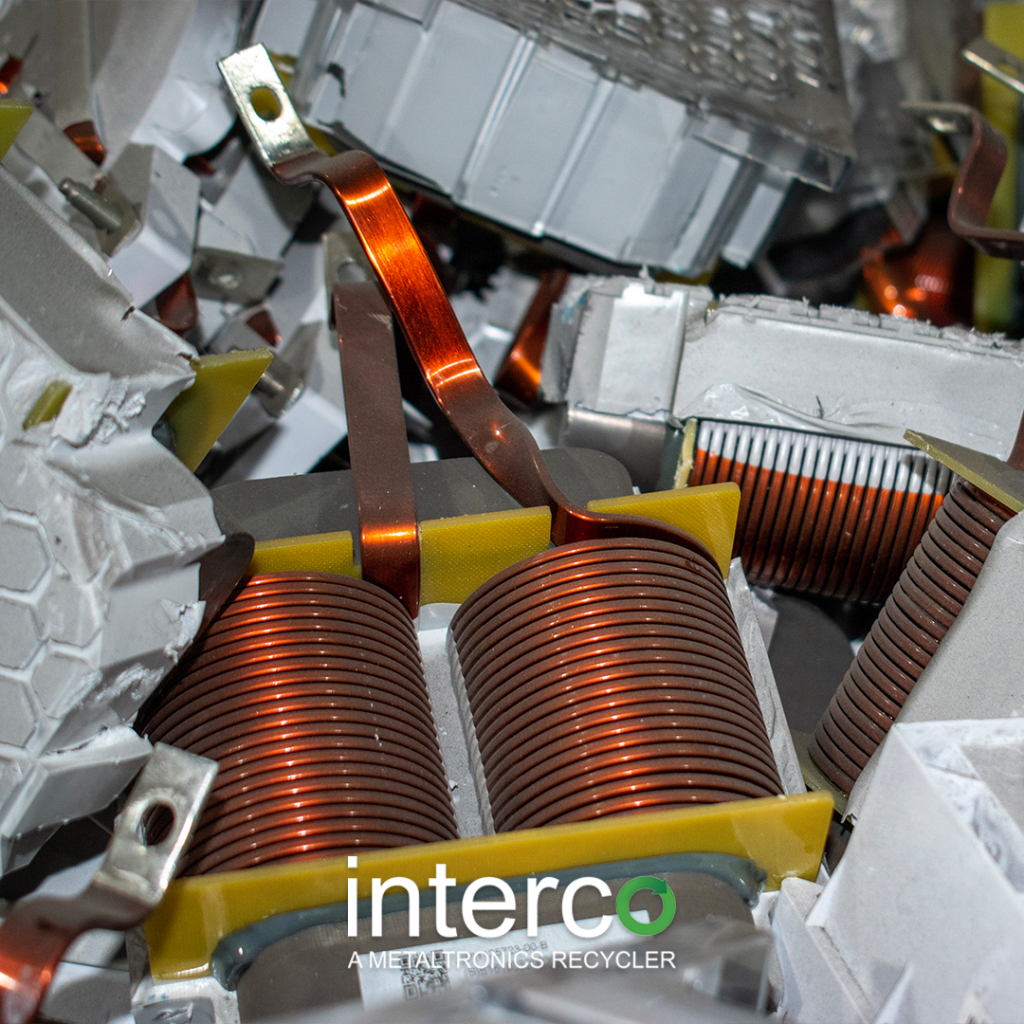

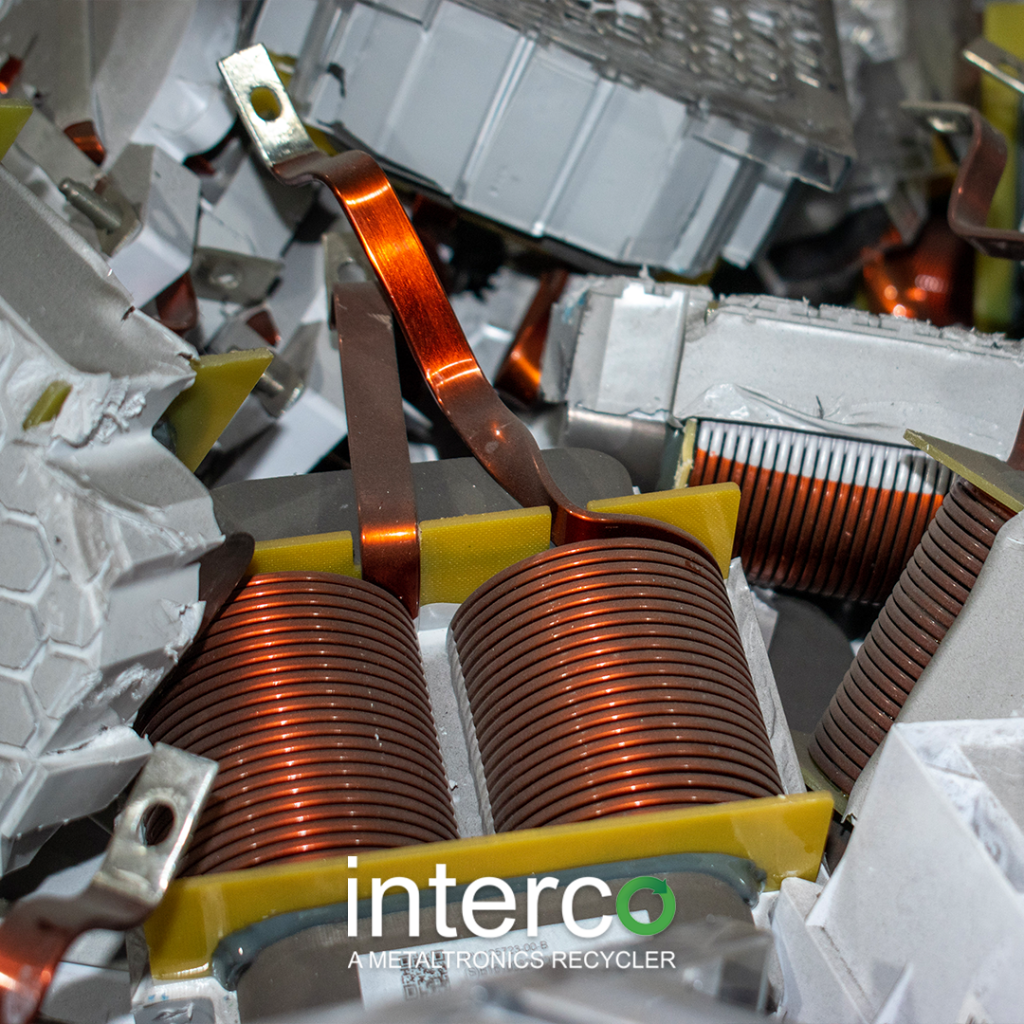

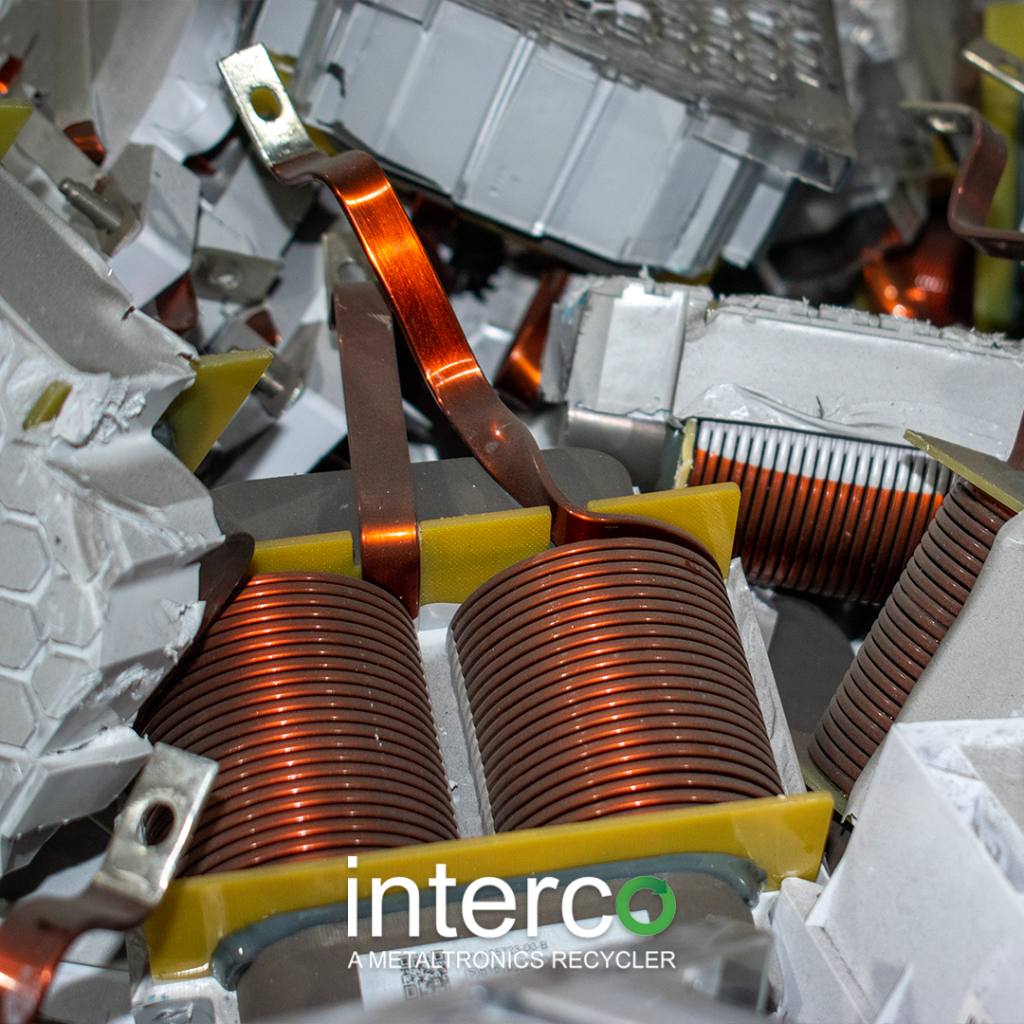

Various metals and minerals create a lithium-ion battery. These metals, like other batteries, include:

- Nickel

- Cobalt

- Copper

Thus, it is important that the disposal service chosen can recycle lithium-ion batteries.

Rapid growth in the market for electric vehicles and lithium-ion powered devices presents serious waste-management challenges for recyclers at end-of-life.

Why Choose a Certified Scrap Lithium-ion Batteries Recycler?

Lithium-ion batteries contain these rich minerals and valuable metals that allow for extended manufacturing of batteries if recycled. Although, these valuable metals and other materials are accompanied by harmful chemicals as well.

A certified scrap lithium-ion batteries recycler processes scrap lithium-ion batteries with the goal of extracting the valuable metals from the battery and avoiding further pollution to the environment.

These recycling centers like Interco are reputable and certified in battery recycling.

There are a few environmental, quality, safety, and security measures built into these certifications to hold recyclers accountable for how they handle their clients’ assets. Founded in 1996, Interco continues to comply with the proper certifications and regulations in the industry.

Lithium-ion batteries can be recycled, but only at permitted treatment facilities.

When discarded, they must be disposed of at a certified scrap lithium-ion batteries recycler. Of course, the electrical hazard needs to be carefully considered.

Lithium batteries are generally safe and unlikely to fail, but only so long as there are no defects, and the batteries are operating under normal conditions. As lithium batteries fail to operate safely or are damaged, they may present a fire hazard.

Recycling Scrap Lithium-Ion Batteries

A certified scrap lithium-ion batteries recycler can buy or sell scrap lithium-ion batteries with the goal of extracting the valuable metals from the battery. Recycling centers can offer your company cash for your scrap when following the recycling process. Therefore, before retrieving the metals, recyclers follow a recycling process.

- Prior to the recycling process, companies need to deactivate the batteries.

- Lithium-ion batteries are put in a specialized room that is oxygen-free.

- Hydrometallurgy is the process of extracting metals from ores.

- Next, the leaching process refers to the process of using aqueous solutions to extract metal from other metal-bearing materials.

- Separate the battery components into three different items. These items may include cobalt, steel, aluminum, copper, plastic.

- As a result, recyclers retrieve these valuable metals, and companies sell them.

Consequently, batteries that are not transported to a recycling center end up in a landfill. As a result, Interco performs the recycling process for lithium-ion batteries carefully on a facility comprised of five buildings — approximately 400,000 square feet total — on more than 35 acres.

Interco, as an ISO 9001 Quality Management System certified company, continues an international-accepted uniform quality system, supplies the highest levels of customer service, and manages its material in the highest regard. Additionally, all material will be recycled by approved ISO 14001 Environmental Management and ISO 45001 Occupational Health and Safety best practices. As a result, Interco confirms the exact weights and records upon receipt, and we issue a written certificate of recycling.

Interco is a Certified Scrap Lithium-ion Batteries Recycler

In conclusion, Interco has the capability as a certified scrap lithium-ion batteries recycler to buy and sell scrap lithium-ion batteries for recycling purposes. Recycling allows for the recovery of rich metals and reduces the harmful effects on the environment that improper disposal causes. Furthermore, the team at Interco accepts, processes, trades, and recycles an array of nonferrous metals. Interco recycles batteries of all shapes, sizes, and chemistry. Thus, the team at Interco continues to lead the way in terms of innovative industrial recycling solutions. Consequently, to discover more about how to recycle lithium-ion batteries, click here.