What is eWaste Recycling?

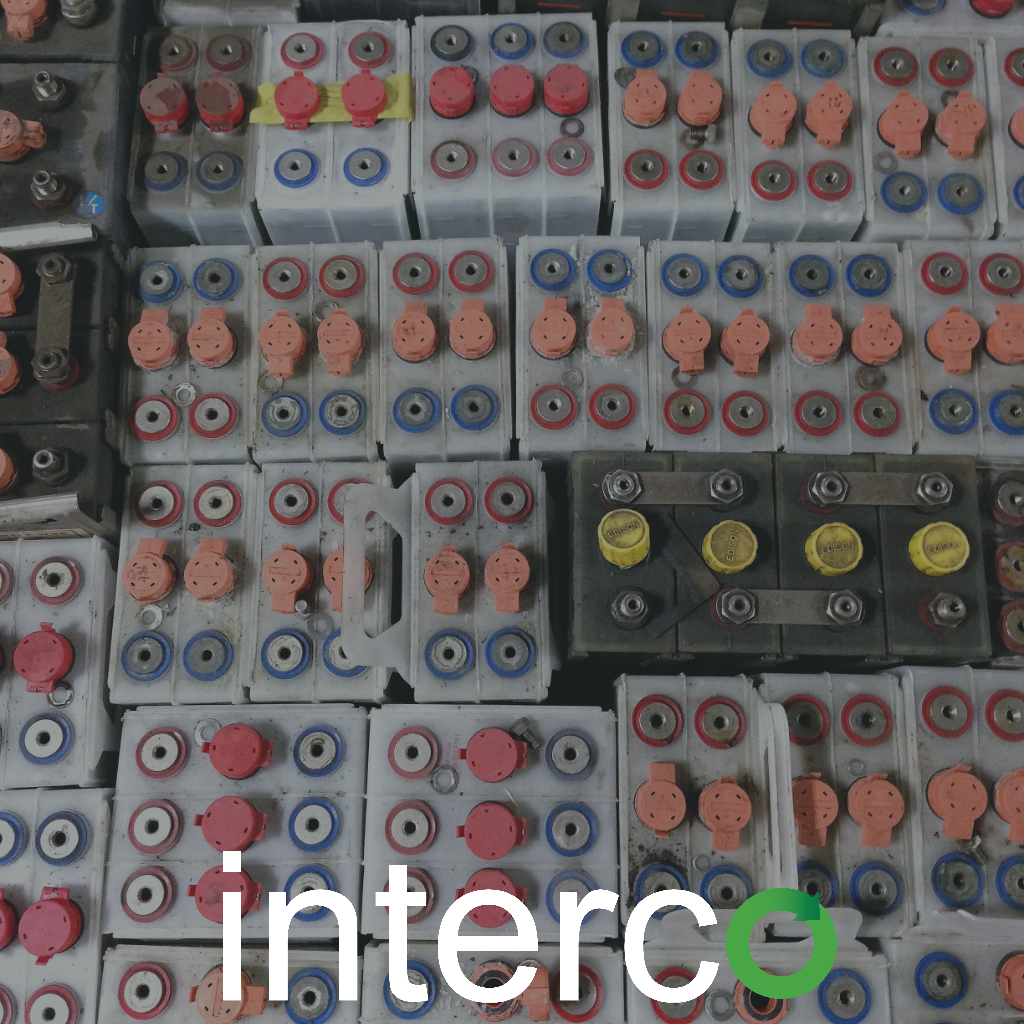

Recyclers use the term eWaste or eScrap to describe business and consumer electronic products on the verge of retirement or already spoiled. Both terms represent end-of-life computer and electronic devices. For example:

- Computers

- Phones

- Televisions

- Fax machines

- Stereos, etc.

Recycling computers and electronics helps re-purpose these devices, though there are still large amounts of eWaste yet to be dumped to landfills. The importance of eWaste recycling grows daily. The rate of eWaste recycling today is still very poor due to improper knowledge about this process.

Why Should You Recycle Computers and Electronics?

Rich Source of Raw Material: Approximately 10–15% of gold is recoverable from e-waste worldwide. Also, it is said that eWaste contains deposits of precious metals that estimate between 40 and 50 times costlier and richer than their ores beneath the earth’s surface.

Solid Waste Management: There is excessive land fill and solid waste. eWaste recycling helps prevent further degradation if agricultural land and curbs pollution.

Toxic Materials: Old electronic gadgets and devices contain toxic materials like mercury, lead, chromium and cadmium. Therefore, eWaste recycling helps assure proper processing, so that these devices do not release these toxic gases into the environment.

How to Recycle E-waste

eWaste recycle requires a degree of care. Execute these steps carefully:

- Collection of the eWaste from dumping or deposit points.

- Break them with a hammer or by hammering.

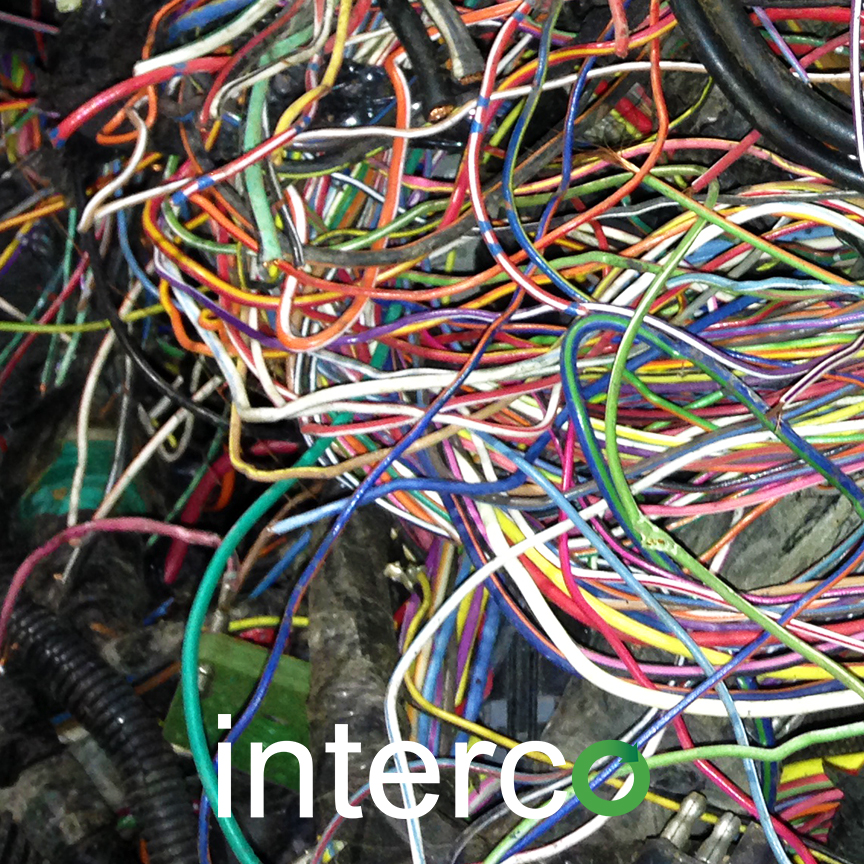

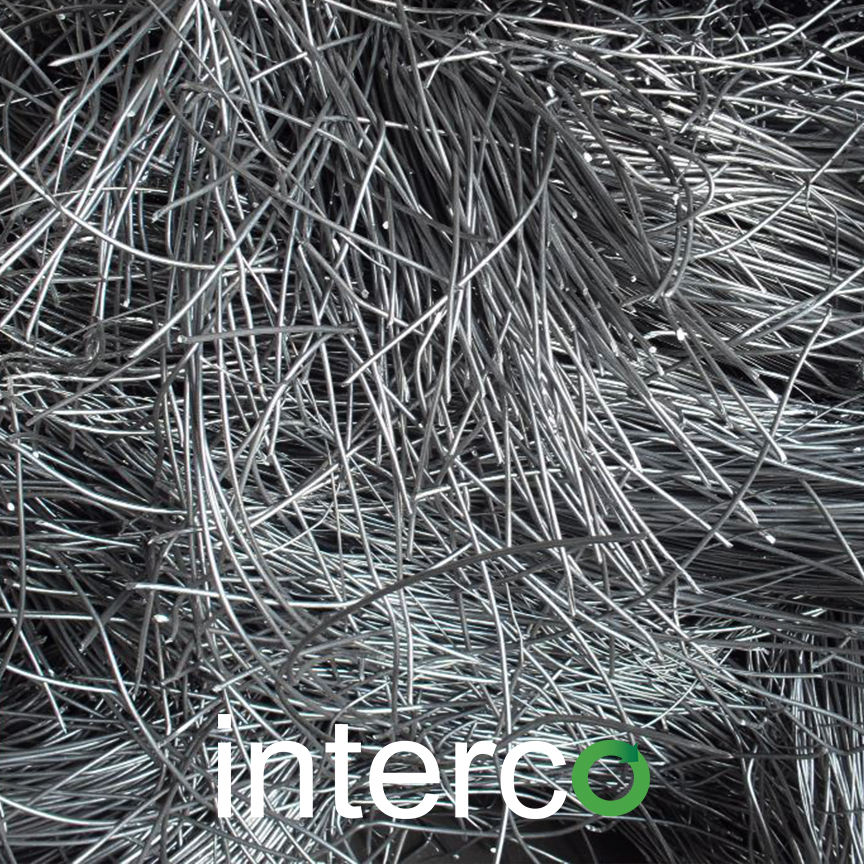

- Separate individual components i.e. plastic, glass, copper, and other metallic materials.

- Take individual materials to their different recycling points for further processing.

- Pack non-recyclable materials and properly dispose them.

The disposal process takes a degree of care because the company keeps the environment in mind and abides by all safety and regulation laws. Recyclers must follow all EPA regulations during the processing of the computer and electronics items.

Benefits of E-waste Recycling

The list benefits of eWaste recycling to man and the environment at large grows daily.

Reduces Water, Air and Soil Pollution:

Because of the toxic constituents of eWaste, indiscriminate dumping or disposal can be dangerous to human health and the environment. Residents of areas polluted by the improper disposal of computer and electronics risk developing serious diseases and experiencing certain medical conditions due to inhalation of these harmful substances.

In addition, unprocessed eWaste left on the ground seeps out chemicals that affect the soil, rendering it not conducive for agricultural use. Furthermore, when rain falls, these chemical wash off from the eWaste dumps and flows into rivers and streams. This could contaminate drinking water. Proper eWaste recycling reduces all these forms of pollution.

It Protects Natural Resources:

Most of the resources in nature are non-renewable. eWaste recycling allows the separation of these valuable materials and their recovery. In this way, companies can produce new products using the same materials. This helps reduce pollution, save energy, and protect natural resources.

Reduces the Space Required for Landfills:

Waste is a global problem and governments around the world are in search to reduce the space need for landfills. Sometimes, these landfills are covering areas that are suitable for agriculture or even for housing. Also, most of the wastes left in landfills cannot dissolve and that’s when the real problems begin. By executing eWaste recycling, you will be able to reduce the space needed for landfills and directly reduce pollution.

eWaste Recycling Creates Employment:

If governments properly educate and enlighten citizens on the importance of eWaste recycling, then people will open new electronic waste recycling companies. Also, the existing ones like Interco will employ more workers that will help in the process. By utilizing this effort, governments support the local economy and protect nature at the same time.

Conclusion

The computer and electronics around us from old computers, laptops, and monitors all fall into eWaste. To learn more about eWaste recycling, contact Interco here.